Description

Product Description

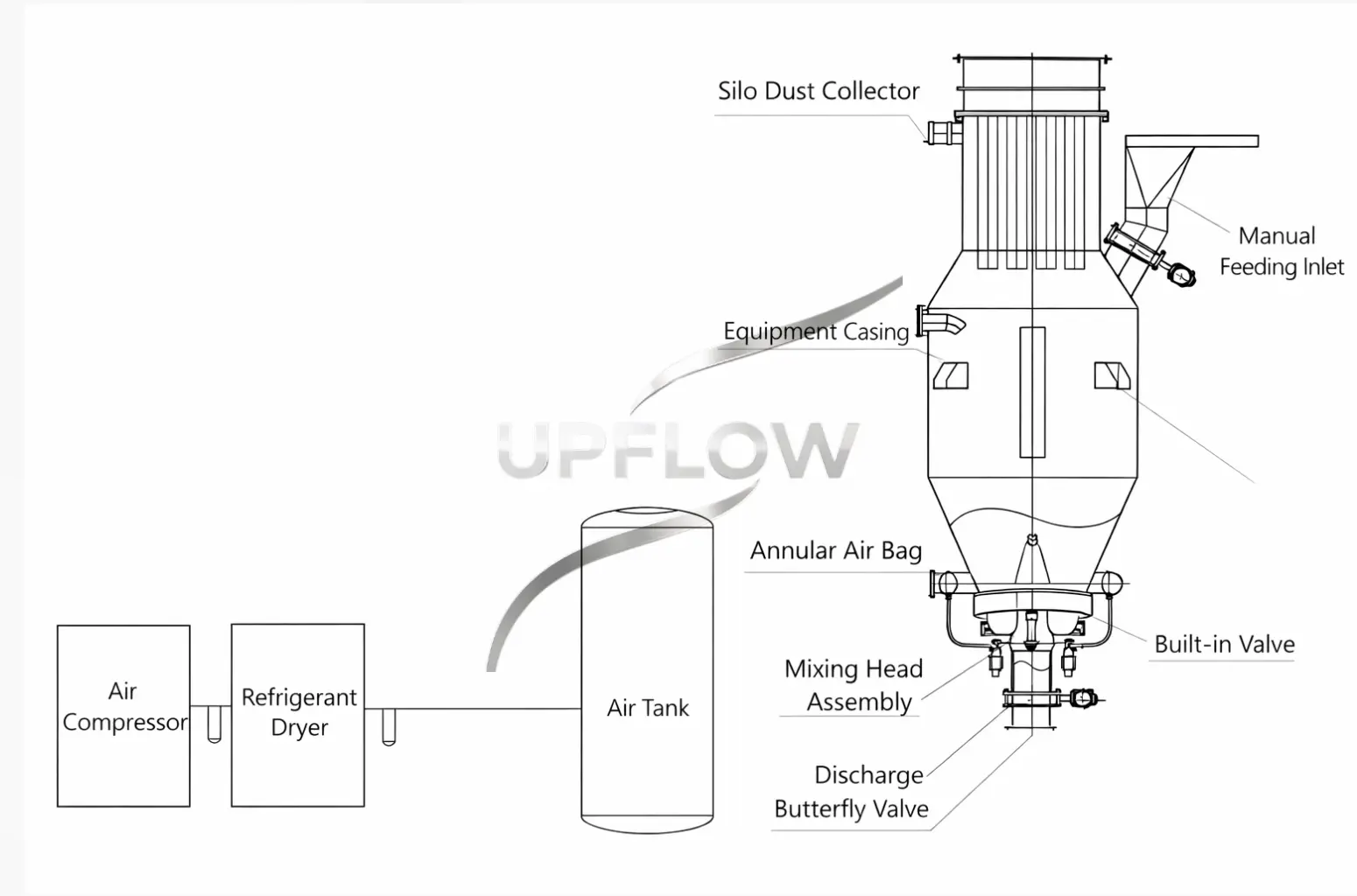

The airflow mixer uses compressed air as the power source. Compressed air enters the mixing cylinder through the mold nozzles on the mixing head. The airflow drives the material to spiral upwards along a specific trajectory, forming a fluidized mixing state in the mixing cylinder. Through pulsed action, the material is repeatedly mixed, ensuring thorough, rapid, and uniform mixing.

It solves the long-standing problem of mechanical mixing being unable to handle large-scale mixing. With this large-scale mixing capability, the product can be mixed in batches of up to 50 cubic meters, thus increasing product batch sizes. Because there are no mixing arms or other transmission devices, it can effectively control the mixing of special materials that are abrasive, corrosive, flammable, explosive, or have poor fluidity or easily breakable particles. Through years of application in customer facilities, our company has mastered and accumulated rich experience in the mixing of different materials. Through continuous improvement of the mixer’s performance and technology, we have achieved higher mixing uniformity (CV value <2.5-5%) and shorter mixing times (4-12 minutes/batch).

Application Areas

Suitable for automatic bag opening and unloading of dry powdered and granular materials in food, pharmaceutical, chemical, metallurgical, new materials, and other fields, such as calcium nitrate, magnesium oxide, quartz sand, limestone, sawdust, activated carbon, PVC powder, fly ash, etc.

Product Features

1.Large Capacity Mixing: Can mix 1-100 cubic meters in a single batch.

2.Short Mixing Time: Each batch takes only 4-12 minutes to mix (depending on material characteristics).

3.No Mechanical Transmission: Suitable for special materials that are abrasive, corrosive, flammable, explosive, or have poor flowability or easily breakable particles. It prevents friction and heat generation, eliminates mechanical wear, avoids lubricant contamination, minimizes particle size damage, features corrosion-resistant coating on the inner wall, and uses nitrogen gas for effective control during the mixing of flammable and explosive products.

4.Strong Versatility: One machine can perform four functions: ① Mixing; ② Negative pressure conveying vacuum feeder; ③ Positive pressure conveying receiving bin; ④ Storage silo, saving space and facilitating production line integration.

5.Easy Cleaning: The equipment body has no dead corners or material residue, and is equipped with multiple pulse blowing points for convenient and quick disassembly and cleaning.

6.Convenient Sampling: The equipment body has three sampling ports (upper, middle, and lower) for convenient and quick sampling.

7.High Efficiency and Energy Saving: Unit energy consumption is 50% less than mechanical mixing.

8.High Filling Coefficient: Depending on the material characteristics, the filling coefficient can reach 60-90%.

9.High Degree of Automation: Controlled by an on-site PLC touch screen system, allowing for one-button operation. It can also be integrated with the production line system and communicate with the DCS system for control.

Product Description

The air mixer utilizes the kinetic energy generated by the rapid expansion and pressure release of compressed air to lift, move, tumble, and roll dry materials within the silo. Compressed air enters the material silo upwards through several nozzles in a pulsed cycle. Through pre-set pulse width and interval times, the mixing process effectively lifts the central portion of the material while simultaneously moving the peripheral portions downwards, tumbling and rolling the material to achieve uniform mixing. During the mixing cycle, the consumed compressed air is typically separated from the material through a dust collector at the top of the silo, and the air is discharged through a filter. The material is collected within the silo by the filter and then recycled back into the mixed material. A discharge cone valve is used to eliminate dead zones during mixing and significantly reduce material segregation during discharge.

Working Process: The operator loads the material into the mixer in a single batch or through other conveying methods, generally filling 60%-70% of the mixer’s total volume. The inlet valve is then closed. The equipment starts, and the automatic control program runs repeatedly. After the program finishes, material samples can be taken from the sampling ports for comparison. The sampling ports are located at the top, middle, and bottom of the silo. If the samples are satisfactory, the material is discharged.

Product Specifications

| Model | UPFLOW-400 | UPFLOW-600 | UPFLOW-800 | UPFLOW-1000 | UPFLOW-1200 |

| Total volume(m3) | 1-3 | 3-10 | 10-30 | 30-50 | 50-100 |

| Power source pressure | 0.6-1.5(Mpa) | ||||

| Load factor | 60-70% | ||||

| Silo dust collector | The filter element can utilize coated fabric bags, coated filter cartridges, pulse jet cleaning. | ||||

Product Cases