Description

Product Overview

The Plate Chain Bucket Elevator (NE Series) is a highly efficient and energy-saving vertical conveying equipment designed for transporting powdered, granular, and small lump materials. Widely used in industries such as cement, mining, chemicals, construction materials, and grain, it features high-strength alloy plate chains as traction components. With advantages like large conveying capacity, high lifting height, robust structure, and long service life, it is particularly suitable for handling high-temperature, highly abrasive, or heavy materials.

Key Features (Advantages)

✅ High Conveying Capacity – Compared to traditional chain bucket elevators, the NE Series offers a larger capacity, ranging from 50 to 500 m³/h.

✅ High Lifting Height – Capable of lifting materials up to 50 meters or more, ideal for high-rise conveying needs.

✅ Wear-Resistant & Durable – Uses high-strength plate chains for excellent wear resistance and extended service life.

✅ Wide Temperature Range – Can handle materials with temperatures up to 250°C.

✅ Stable Operation, Low Maintenance – Plate chain transmission reduces friction and maintenance frequency.

✅ Excellent Sealing, No Dust Leakage – Compact structure minimizes material leakage, meeting environmental standards.

Applications (Industries)

Construction Materials Industry – Transporting cement, limestone, sand, and gypsum.

Chemical Industry – Handling fertilizers, mineral powders, alumina, and titanium dioxide.

Mining Industry – Conveying coal powder, ores, iron powder, and metallurgical slag.

Grain Industry – Moving soybeans, corn, wheat, and feed pellets.

Environmental Protection – Lifting fly ash, sludge, and solid waste materials.

Models (Equipment Models)

|

Model |

Capacity (m³/h) | Bucket Type | Bucket Capacity (L) |

Max. Lifting Height (m) |

Chain Pitch (mm) |

|

NE15 |

15 | Deep Bucket | 2.5 | 30 | 152.4 |

|

NE30 |

30 | Deep Bucket | 5.9 | 40 | 152.4 |

|

NE50 |

50 | Deep Bucket | 11.2 | 45 |

200 |

| NE100 | 100 | Deep Bucket | 22.4 | 50 |

250 |

| NE150 | 150 | Deep Bucket | 33.6 | 50 |

250 |

| NE200 | 200 | Deep Bucket | 44.8 | 50 |

250 |

|

Custom Models Available |

|||||

Technical Parameters

|

Parameter |

Description |

|

Conveying Method |

Vertical Lifting |

|

Material Type |

Powders, Granules, Small Lump Materials |

| Bucket Material |

Carbon Steel / Stainless Steel 304 / 316L |

| Chain Material |

High-Strength Alloy Steel |

|

Drive Method |

Motor-Driven, Sprocket Transmission |

|

Power Range |

2.2kW – 75kW |

|

Max. Lifting Height |

50m (Customizable) |

| Operating Temperature |

-20℃ ~ 250℃ |

|

Feeding Method |

Gravity Feeding (Material Flows into Buckets) |

| Discharge Method |

Gravity Discharge (Material Falls by Weight) |

Working Principle

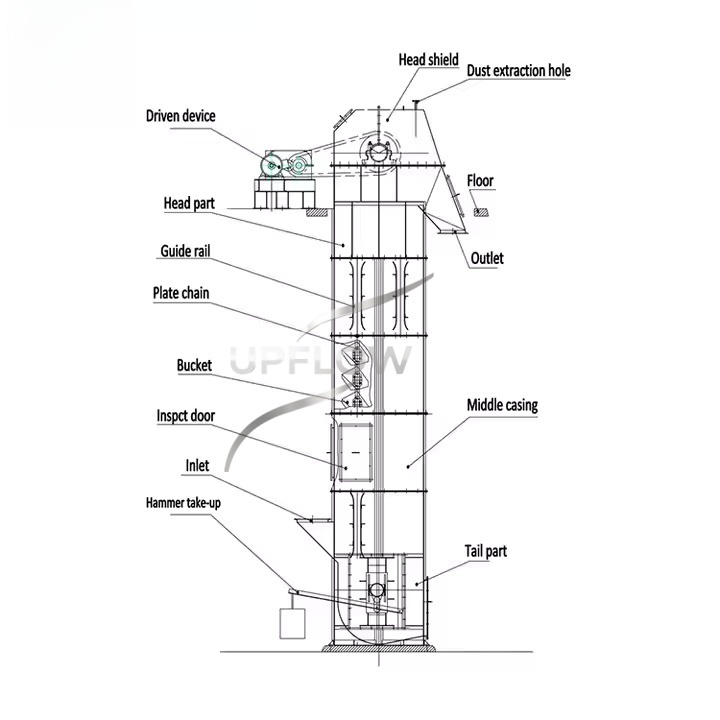

The Plate Chain Bucket Elevator consists of a casing, drive unit, upper head, middle body, lower base, plate chains, and buckets.

1.Material enters the buckets through the inlet and is lifted by the plate chains.

2.At the top, the material is discharged by gravity.

3.The empty buckets return to the bottom to reload, forming a continuous conveying process.

Selection Guide

Material Characteristics – For high-temperature, hard, or abrasive materials, choose wear-resistant alloy chains.

Conveying Capacity – Select models from NE15 to NE200 based on required capacity.

Lifting Height – Determine the required height and choose appropriate motor power.

Industry Requirements – For cement and mining industries, opt for fully enclosed designs to minimize dust leakage.

Product Images

Call to Action

Looking for a reliable Plate Chain Bucket Elevator for your material handling needs? Contact us today for a customized solution tailored to your industry requirements!