Description

E-mail: in**@************ry.com

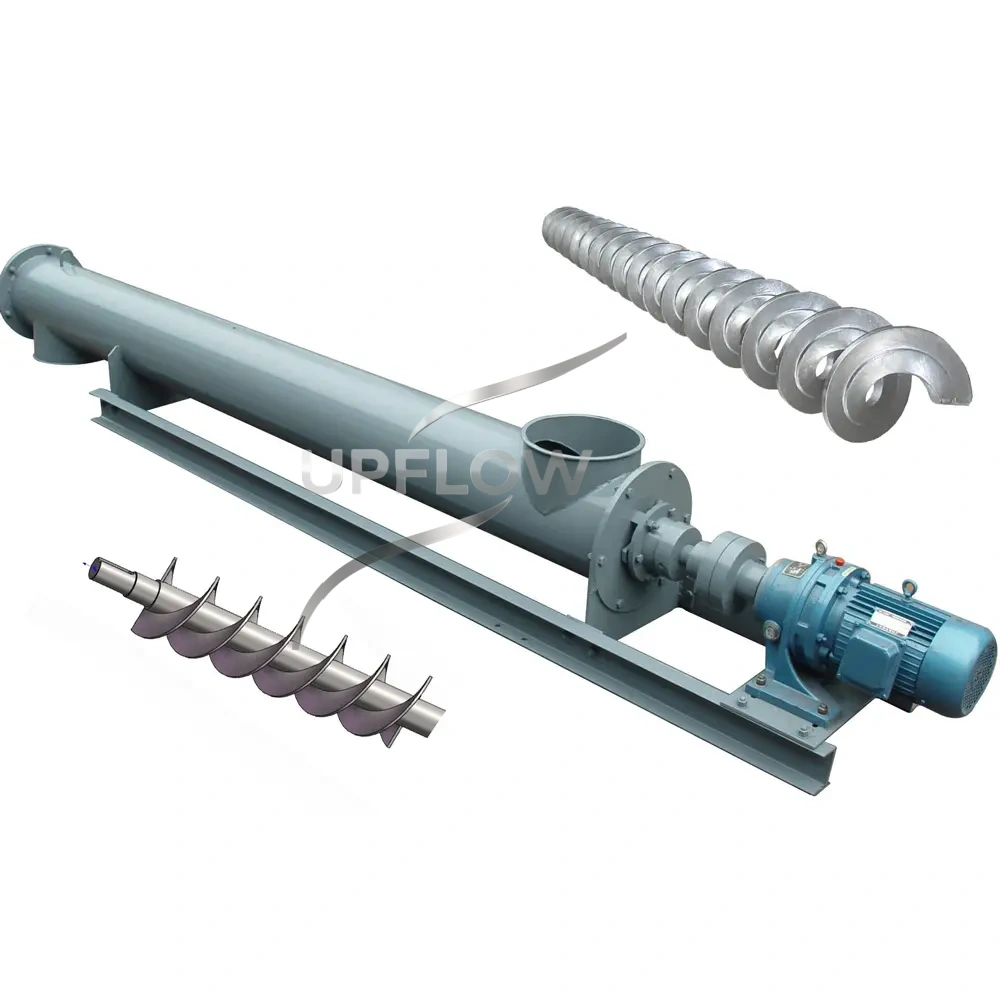

As a professional screw conveyor manufacturer and screw conveyor factory, Upflow industry specializes in designing and manufacturing a wide range of screw feeders and auger conveyors to meet diverse bulk material handling needs. Our product line includes U-type screw conveyors, tubular (pipe) screw conveyors, and shaftless screw conveyors, offering solutions for various industries such as food, chemical, plastic, and wastewater treatment.

Product Cases

Tubular Screw Conveyor

Model Series: LSY

Our enclosed screw conveyor, also called pipe screw conveyor, is designed for dust-free and safe material transfer. It’s ideal for vertical and inclined applications.

Features:

Fully enclosed tube-type design for dust-free, sealed transport.

Central shaft structure with high precision and low contamination risk.

Suitable for vertical or inclined conveying.

Custom lengths and long screw conveyor configurations available

Applications:

Used for fine, dusty or hazardous powders like calcium carbonate, silica, starch, milk powder, pharmaceutical powders.

Common in chemical, pharmaceutical, food, and environmental industries.

Specifications:

Diameter: 88–500 mm

Conveying angle: 0°–60°

Easy integration with dosing or weighing systems

Materials: Carbon steel, SS304, SS316L

U-Type Screw Conveyor

Model Series: LS

The U-type screw conveyor is one of the most common screw feeder machines, known for its open trough and ease of maintenance. This type of helical conveyor is ideal for horizontal or slightly inclined material transport.

Features:

Available in carbon steel or stainless screw conveyor design

Traditional trough design with a central shaft and helical blade.

Ideal for horizontal or slightly inclined conveying.

Easy to maintain and install, cost-effective.

Applications:

Suitable for conveying dry powders, granules, and pellets such as cement, fly ash, flour, plastic granules, feed, etc.

Commonly used in cement plants, feed mills, plastic compounding, grain storage.

Specifications:

Diameter: 100–1500 mm

Length: Up to 30 meters

Inclination angle: 0°–50°

Materials: Carbon steel or stainless steel

Shaftless Screw Conveyor

Model Series: WLS

Features:

No central shaft; uses a thicker spiral blade for conveying.

More efficient in handling sticky, viscous, or fibrous materials.

Reduces clogging, especially suitable for wet or semi-solid materials.

Applications:

Ideal for sewage sludge, pulp, food waste, biomass, or chemical residues.

Common in wastewater treatment plants, food processing, paper mills, mining field.

Specifications:

Blade outer diameter: ⌀120–500 mm

Conveying capacity:2-70m³/h

Fully enclosed structure, minimizes odor leakage

Optional: Liner plates for wear resistance

Model Selection Guide

| Model | Type | Best for | Key Advantages |

| LSY | Tubular | Dusty/fine/hygienic materials | Enclosed, dust-free, safe transport |

| LS | U-shaped | Dry powder, granules | Low cost, easy to maintain |

| WLS | Shaftless | Sludge, sticky, fibrous materials | No clogging, suitable for wet material |

Materials: Carbon steel, SS304, SS316L, ceramic

Motor brands: Siemens, SEW, ABB, custom brands

Surface treatment: internal and external surface treatment, paint,sandblasting, spraying, polishing for food-grade use

E-mail: in**@************ry.com