Description

Product Overview

The Shaftless Screw Conveyor (WLS Series) is a specialized conveying equipment designed for handling high-viscosity, tangled, and sticky materials. Its unique shaftless structure ensures smooth operation, eliminating common issues like material wrapping and clogging found in traditional screw conveyors. Ideal for industries such as wastewater treatment, waste management, chemicals, food processing, and mining, it is particularly suitable for transporting sludge, municipal waste, fly ash, and other high-moisture, high-viscosity materials.

Key Features (Advantages)

✅ Shaftless Design for Smooth Conveying – Eliminates the central shaft to prevent material wrapping and clogging, perfect for sticky and tangled materials.

✅ Excellent Sealing, Eco-Friendly – Fully enclosed structure prevents dust leakage and odor diffusion, meeting environmental standards.

✅ High-Wear-Resistant Lining, Low Maintenance – Uses wear-resistant polyethylene (PE) or stainless steel lining to extend service life and reduce maintenance frequency.

✅ Adjustable Conveying Angle – Supports horizontal and inclined conveying to adapt to various working conditions.

✅ Handles High-Moisture Materials – Capable of transporting sludge, wet waste, slurry, and chemical waste that traditional conveyors struggle with.

Applications (Industries)

Environmental Protection – Wastewater treatment plants, waste management stations, solid waste processing centers.

Chemical Industry – Transporting chemical waste, paste-like materials, and fly ash.

Food Industry – Handling food residues and kitchen waste.

Mining & Construction – Conveying sand, lime paste, and coal slag.

Agriculture – Transporting livestock manure and organic fertilizers.

Models (Equipment Models)

|

Model |

Screw Diameter (mm) | Capacity (m³/h) | Conveying Length (m) |

Inclination Angle (°) |

|

WLS200 |

200 | 5-15 | 10 | ≤30° |

|

WLS250 |

250 | 10-25 | 15 | ≤30° |

| WLS315 | 315 | 20-35 | 20 |

≤30° |

| WLS400 | 400 | 30-50 | 25 |

≤30° |

|

Custom Models Available |

||||

Technical Parameters

|

Parameter |

Description |

|

Conveying Method |

Horizontal / Inclined Conveying |

|

Material Type |

High-Viscosity, Tangled, Wet Materials |

| Screw Material |

Carbon Steel / Stainless Steel 304 / 316L |

| Trough Material |

Carbon Steel / Stainless Steel |

|

Wear-Resistant Lining |

Ultra-High Molecular Weight Polyethylene (PE-UHMW) / Stainless Steel |

|

Drive Method |

Direct Motor Drive / Chain Drive |

| Power Range |

1.5kW – 15kW |

| Max. Conveying Length |

25m (Customizable) |

|

Operating Temperature |

-20℃ ~ 200℃ |

Working Principle

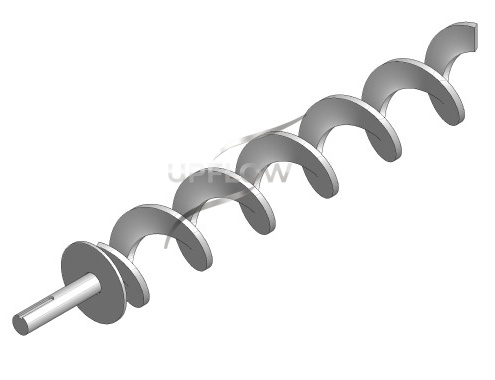

The Shaftless Screw Conveyor consists of a drive unit, shaftless screw blade, U-shaped trough, wear-resistant lining, and inlet/outlet ports. The motor drives the screw blade to rotate, pushing materials from the inlet to the outlet through the trough, achieving continuous conveying.

Selection Guide

Material Characteristics – For high-viscosity, tangled, and high-moisture materials, choose the shaftless design.

Conveying Distance – Determine the required length and select appropriate power and screw diameter.

Conveying Angle – Excessive inclination may reduce efficiency; recommended angle ≤30°.

Industry Application – For wastewater treatment and waste management, choose 304 or 316L stainless steel for enhanced corrosion resistance.

Product Images

Call to Action

Looking for a reliable Shaftless Screw Conveyor for your material handling needs? Contact us today for a customized solution tailored to your industry requirements!