Description

Product Overview

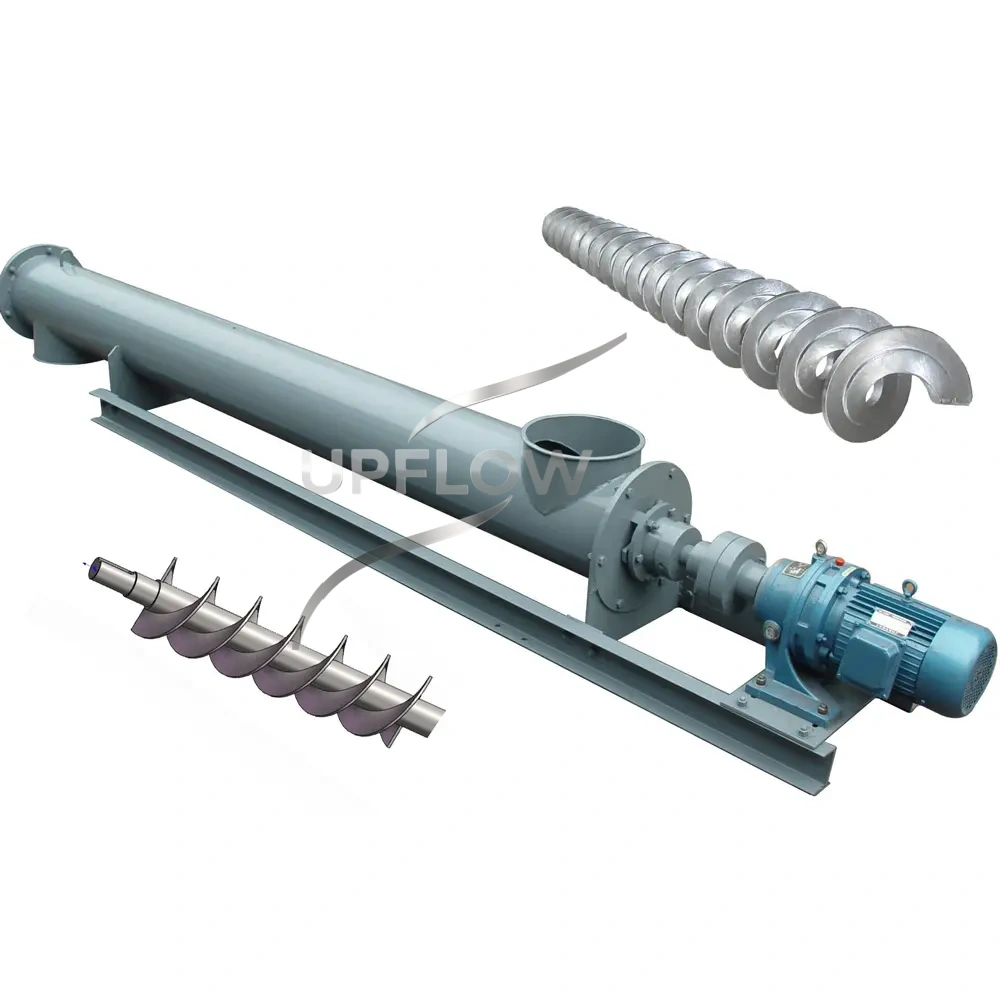

The Tube Screw Conveyor is a fully enclosed conveying equipment designed for horizontal, inclined, or vertical transportation of powdered, granular, and small lump materials. Its cylindrical tube structure effectively minimizes dust pollution, ensuring sealed and efficient material handling. Widely used in industries such as construction materials, chemicals, food, agriculture, and environmental protection, this conveyor is a reliable solution for diverse material handling needs.

Key Features (Advantages)

✅ Excellent Sealing Performance – Fully enclosed tube design prevents dust leakage, ensuring eco-friendly and efficient operation.

✅ High Conveying Efficiency – Optimized screw blade design reduces material residue and improves conveying capacity.

✅ Wide Adaptability – Capable of handling various materials, including powders, granules, wet, and sticky substances.

✅ Compact Design – Space-saving structure ideal for confined spaces.

✅ Easy Maintenance – Modular design simplifies installation, disassembly, and maintenance.

Applications (Industries)

Construction Materials Industry – Conveying cement, lime, sand, and gravel.

Chemical Industry – Transporting plastic pellets, resin powders, and chemical raw materials.

Food Industry – Handling flour, sugar, grains, and additives.

Agriculture Industry – Moving feed, grains, and fertilizers.

Environmental Protection – Managing sludge, waste, and dust collection.

Models (Equipment Models)

| Model | Screw Diameter (mm) | Capacity (m³/h) | Max. Conveying Length (m) | Inclination Angle (°) |

| LSY160 | 160 | 5-20 | 12 | ≤60° |

| LSY200 | 200 | 10-30 | 15 | ≤60° |

| LSY250 | 250 | 20-50 | 20 | ≤60° |

| LSY300 | 300 | 30-80 | 25 | ≤60° |

|

Custom Models Available |

||||

Technical Parameters

| Parameter | Description |

| Conveying Method | Horizontal / Inclined / Vertical Conveying |

| Material Type | Powders, Granules, Small Lump Materials |

| Screw Material | Carbon Steel / Stainless Steel 304 / 316L |

| Tube Material | Carbon Steel / Stainless Steel |

| Drive Method | Direct Motor Drive / Chain Drive |

| Power Range | 1.5kW – 15kW |

| Max. Conveying Length | 25m (Customizable) |

| Operating Temperature | -20℃ ~ 200℃ |

Working Principle

The Tube Screw Conveyor consists of a drive unit, screw blades, tube body, and inlet/outlet ports. The motor drives the screw blades to rotate, pushing materials from the inlet to the outlet through the tube, achieving continuous conveying.

Selection Guide

Material Characteristics – Consider stickiness and dust generation; choose materials like stainless steel for specific needs.

Conveying Distance – Determine the required length and select appropriate power and screw diameter.

Conveying Angle – Inclination affects efficiency; for angles over 30°, choose a higher-power motor.

Industry Application – Use stainless steel for food and chemical industries to ensure corrosion resistance and contamination-free operation.

Product Images

Call to Action

Looking for a reliable Tube Screw Conveyor for your material handling needs? Contact us today for a customized solution tailored to your industry requirements!